The Future of Style: Checking Out DTF Printing Innovation in the Fabric Market

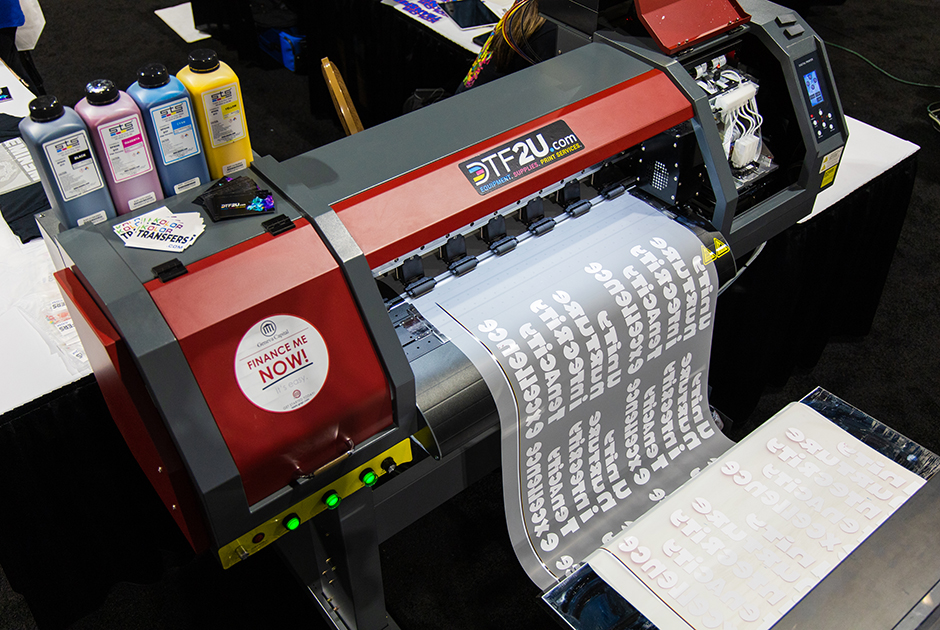

Amongst these advancements, Direct to Film (DTF) printing technology has emerged as an appealing competitor, using one-of-a-kind capacities and opportunities for designers and manufacturers alike. This cutting-edge printing method has triggered rate of interest due to its prospective to revolutionize conventional textile printing processes.

Evolution of Textile Printing

From the old people utilizing techniques like block printing to the electronic transformation of today, textile printing has continuously pushed boundaries. As the craft spread to various other components of the world, new approaches such as screen printing and roller printing arised throughout the Industrial Revolution, revolutionizing the fabric industry.

In the 20th century, advancements in modern technology caused the development of rotating display printing, allowing for faster and extra complex designs. The intro of digital fabric printing in the late 20th century marked a substantial shift towards even more flexible and lasting printing techniques. Today, with innovations like Direct-to-Fabric (DTF) printing modern technology, designers can produce vibrant, thorough prints with higher efficiency and lowered environmental influence. The development of textile printing showcases an abundant history of imagination, ingenuity, and technological progression in the world of style and style.

Benefits of DTF Modern Technology

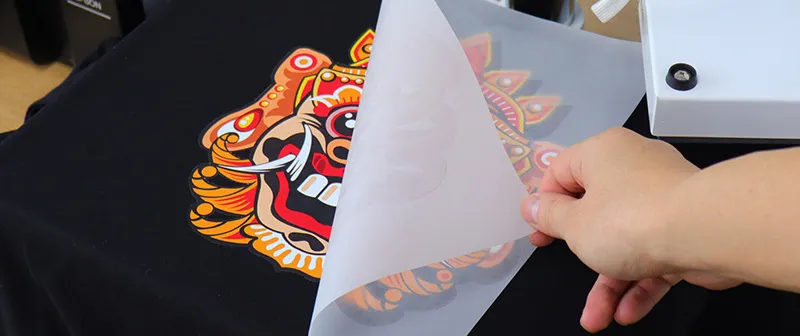

With the evolution of textile printing methods from old approaches like block printing to modern-day innovations such as digital printing, the introduction of Direct-to-Fabric (DTF) innovation has actually dramatically boosted the efficiency and sustainability of textile printing processes. One of the primary benefits of DTF innovation is its capability to directly print styles onto material without the demand for transfer papers, which reduces waste and simplifies the production procedure. In addition, DTF printing allows for greater color vibrancy and detail precision compared to traditional methods, enabling fabric manufacturers to create top quality and elaborate designs with ease.

Moreover, DTF technology is recognized for its versatility, as it can be made use of on numerous kinds of materials, including all-natural fibers like wool, cotton, and silk, along with artificial materials such as polyester and nylon (DTF Printing). This flexibility opens a large range of possibilities for makers and designers to experiment with various structures and materials, bring about even more innovative and unique products in the apparel industry. Overall, the execution of DTF innovation stands for a considerable development in fabric printing, using numerous benefits that add to the future sustainability and creative thinking of the market

Sustainability in Style Production

Emphasizing green methods is extremely important in contemporary style production, straightening with the growing customer demand for lasting products. Over the last few years, the fashion market has actually dealt with raising scrutiny because of its significant ecological influence, including extreme water use, chemical contamination, and fabric waste. As a reaction, several fashion brands are currently including sustainable methods right into their manufacturing processes to lessen injury to the environment.

Sustainability in fashion manufacturing encompasses various facets, such as see post making use of recycled and natural products, reducing energy intake, implementing moral labor practices, and promoting openness throughout the supply chain. Additionally, improvements in technology, like DTF printing, offer chances to additionally boost sustainability in textile production. This modern technology enables precise printing on materials, minimizing ink wastefulness and water usage compared to conventional printing approaches.

Design Flexibility and Modification

In addition, DTF printing assists in personalization on a scale formerly unattainable, permitting personalized apparel and distinct pieces customized to individual choices. Consumers can currently proactively take part in the layout procedure, creating garments that mirror their style and individuality. This personalization not just improves the Learn More consumer experience however also advertises a sense of exclusivity and originality in a market saturated with mass-produced apparel. In general, DTF printing modern technology reinvents the design landscape in the textile sector, providing countless possibilities for imaginative expression and individualized style.

Impact on Supply Chain & Market Trends

DTF printing innovation in the textile industry is reshaping supply chain characteristics and affecting market fads via its effectiveness and personalization abilities. By enabling on-demand printing and eliminating the demand for huge stocks, DTF innovation improves the supply chain process.

Moreover, the modification capacity of DTF printing technology is revolutionizing the marketplace patterns in the textile sector. Customers increasingly look for personalized and one-of-a-kind items, and DTF allows brand names to use bespoke layouts cost-effectively. This personalization capability not just improves customer satisfaction yet likewise opens up brand-new chances for companies to provide to specific niche markets and separate themselves from rivals. As a result, DTF modern technology is driving a shift in the direction of more cutting-edge and customer-centric methods within the fabric industry, forming the future of fashion.

Final Thought

Finally, DTF printing technology is transforming the textile industry by using many benefits such as layout liberty, modification, and sustainability. This cutting-edge technology is reshaping the future of fashion manufacturing, influencing supply chains, and driving market fads in the direction of more eco-friendly and efficient practices. As the market remains to progress, DTF printing will certainly play an essential function in forming the means fabrics are generated and eaten in the years ahead.

From the ancient worlds utilizing methods like block printing to the digital transformation of today, textile printing has constantly pushed boundaries. As the craft spread to other components of the globe, brand-new techniques such as screen printing and roller printing emerged during the Industrial Revolution, revolutionizing the textile sector.

The intro of electronic textile printing in the late 20th century marked a significant shift towards even more lasting and functional printing methods.With the evolution of fabric printing methods from ancient methods like block printing to modern-day advancements such as electronic printing, the intro of Direct-to-Fabric (DTF) innovation has significantly boosted the performance and sustainability of fabric printing processes (DTF Printing).In feedback to the imperative change towards sustainability in style manufacturing, the adoption of cutting-edge innovations Website like DTF printing not only addresses ecological issues yet likewise opens up avenues for unmatched layout flexibility and modification in the textile industry

Comments on “Using the Power of DTF Printing: Strategies for High-Quality Textile Layouts”